KBIOSYSTEMS PORVAIR

SCORPION SBS PLATE HANDLERS

AUTOMATED PLATE AND TUBE HANDLING SYSTEMS

Offering laboratories the ability to step up to automated plate handling with integratable OEM plate handling devices.

Next-generation label-free analysis

BLI is a powerful technology that is flexible, highly-sensitive and accessible. From experiment to analysis, characterise the widest range of molecules on a single easy-to-use platform ― in a single run.

True low volume, high throughput subvisible particle analysis

Aura systems help you develop stable, pure, and efficacious protein, cell, and gene therapies faster. By combining the sensitivity of BMI with fluorescent detection, Aura systems enable high-throughput particle count, size and identification.

Next-generation label-free analysis

BLI is a powerful technology that is flexible, highly-sensitive and accessible. From experiment to analysis, characterise the widest range of molecules on a single easy-to-use platform ― in a single run.

True low volume, high throughput subvisible particle analysis

Aura systems help you develop stable, pure, and efficacious protein, cell, and gene therapies faster. By combining the sensitivity of BMI with fluorescent detection, Aura systems enable high-throughput particle count, size and identification.

AUTOMATED PLATE AND TUBE HANDLING SYSTEMS

Offering laboratories the ability to step up to automated plate handling with integratable OEM plate handling devices.

Home - Suppliers - Kbiosystems Porvair - Scorpion SBS Plate Handlers

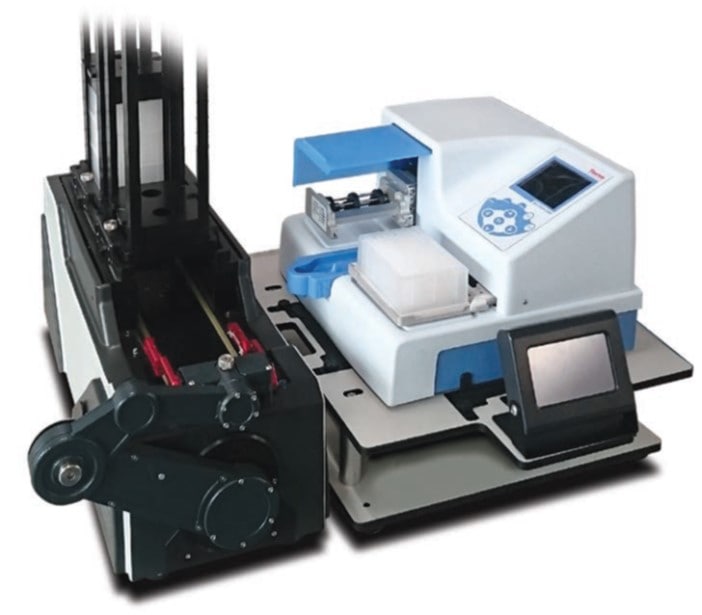

The Kbiosystems automated and semi-automated microplate handling systems offer ideal entry level automation for laboratories requiring reliable, consistent, microplate and tube handling. Offering complete versatility, the Scorpion plate handling series will work with a wide range of plates, tube racks, shallow and deep well formats.

Application flexibility

Scorpion systems allow the use of non-lidded, sealed and lidded plates. Additional functions include plate restacking and an optional upgrade for lid removal. Scorpion systems comes in several formats for left or right feeding, and the XT version with extended arc distance for more utility and flexibility.

Easy and reliable integration

Engineered with robustness in mind, the Scorpion series is easy to program and is operator and integrator friendly. Data control is through direct integration via RS232 link.

Versatile plate compatibility

Scorpion systems are able to use multiple plasticware manufactures plates across applications and can handle all SBS footprint applications and range of racks.

Scorpion SBS Plate Handlers

Scorpion systems handle plates in portrait format, allowing the use of non-lidded and lidded plates. Scorpion systems function through left or right plate feed, offering side placement into the integrated plate handling device.

Scorpion systems have half and full height stackers to accommodate for plate capacity and lab space needs.

Plate restack option allows the user to feed and retrieve plates from a secondary piece of equipment. With need for defined plate stack orientation, the plates can internally be reprocessed into their original line format.

With the addition of the lid removal upgrade, the Scorpion can remove the plate lid prior to placement onto the integrated system (such as a liquid handler), helping decrease possible contamination issues.

Additionally, Kbio offers services for custom plate handling applications, such as their custom designed integration plates suited to different Thermo Combi instruments, to maintain position for repeatable dispensing.

Automated plate handling system

Automated plate handling system with extended arc distance

Scorpion SBS Plate Handlers

| Scorpion | Scorpion XT | |

|---|---|---|

| Plate feed | Left or right | |

| Placement maximum arc | 280 mm | 342 mm |

| Maximum plate capacity * 96-well 384- and 1536-well Deep-well blocks | 50 72 15 | |

| Plate height range | 7 - 48 mm | |

According to the FDA, drug manufacturers can’t just rely on the minimum standards when they release a product. They need to make sure that their products are truly safe and so particles need to be fully characterised throughout the entire development cycle. Halo Labs allow drug companies to make critical therapeutics safer and reduce their development time to help patients in need.

Halo’s Aura line of instruments are the first systems that allow particles to be tested both early in development and later during quality control. The Aura systems can determine if a particle is the result of the drug itself, an ingredient in the liquid crashing out of solution, an external contaminant, or even a cell.

Therapeutic areas: