Solutions for the Medicinal Cannabis Industry

CANNABIS PURIFICATION

Simplify workflows with Gilson’s VERITY CPC Systems

The right choice for cannabinoid purification

Next-generation label-free analysis

BLI is a powerful technology that is flexible, highly-sensitive and accessible. From experiment to analysis, characterise the widest range of molecules on a single easy-to-use platform ― in a single run.

True low volume, high throughput subvisible particle analysis

Aura systems help you develop stable, pure, and efficacious protein, cell, and gene therapies faster. By combining the sensitivity of BMI with fluorescent detection, Aura systems enable high-throughput particle count, size and identification.

Next-generation label-free analysis

BLI is a powerful technology that is flexible, highly-sensitive and accessible. From experiment to analysis, characterise the widest range of molecules on a single easy-to-use platform ― in a single run.

True low volume, high throughput subvisible particle analysis

Aura systems help you develop stable, pure, and efficacious protein, cell, and gene therapies faster. By combining the sensitivity of BMI with fluorescent detection, Aura systems enable high-throughput particle count, size and identification.

The right choice for cannabinoid purification

Home - Natural Product Purification - Medicinal Cannabis

Gilson’s line of VERITY Centrifugal Partition Chromatography (CPC) instruments deliver high yielding, efficient and scalable extraction and purification solutions to the medicinal cannabis industry. Being a silica-free technology makes CPC very cost-effective, and it’s dramatically reduced solvent use results in a more environmentally-friendly, green extraction method.

High yield, reproducible, fast and scalable

Easy scale-up with fully integrated systems providing high yields, high purity, high speed and minimal product loss. Future proof your process with the flexibility for research, pilot and industrial scale production on a GMP compatible system.

An efficient, cost-effective green technology

CPC being a silica free technology means there is no need to replace columns or recycle silica. CPC’s capacity to recycle solvent saves you up to 80% on solvent use compared to solid-phase extraction methods.

Helping our customers achieve success

With over 40 years of experience in preparative and industrial chromatography, Gilson offers expertise and worldwide services to support you. From lab to industrial scale, Gilson have supported hundreds of cannabis scientists and technicians around the world with purification services and systems.

Solutions for the Cannabis Industry

Introduction to CPC

Natural product purification systems

Solutions for the Cannabis Industry

Introduction to CPC

Natural Product Purification Systems

Chromatographic purification of natural compounds presents many challenges to scientists because of the complex nature of the starting matrices that are used in the process. Rather uniquely, CPC uses both liquid stationary and mobile phases and as such can handle heavily contaminated, complex starting materials such as direct extracts from many biological sources.

Separation is based on liquid-liquid partitioning:

From lab to industrial scale, Gilson offers complete cannabinoid purification solutions

Gilson don’t just develop market leading technology. Their dedicated and experienced teams are available to make sure that you get the best from their systems with a range of purification services including engineering design, application development, feasibility and scale-up studies, qualification support, and installation services as part of operational ramp-up.

Solve Scientific as Gilson’s exclusive instruments representative, have local staff each with over 25 years’ experience working with Gilson. Together, with the backing of a global network of CPC Application Specialists, CPC Service & Validation Engineers, and factory support from Gilson’s CPC Centres of Excellence, Solve Scientific can uniquely provide Australian and NZ customers easily accessible local expertise with applications tailored to serve business strategies, and service and support to keep instruments running at peak performance.

| Your needs, our goal | Assess the potential of your sample | Perform Proof of Concept up to process scale | Optimise your own production resources |

|---|---|---|---|

| How we can support you | 1. Screen available feasibility studies | 4. Perform the intensification and scale-up studies | 7. Assist with the organisation of the production process |

| 2. Develop methods optimised for your sample | 5. Produce up to kilograms of pure molecules (as raw material or for trials) | 8. Train your teams at a Gilson Purification centre and/or on-site | |

| 3. Produce up to several grams of pure molecules (as a standard or for trials) | 6. Review the economics and risks related to large scale production | 9. Provide support and equipment through the operational ramp up stage |

Whether you are at the beginning of your journey or already at production stage, contact us with any questions you might have or to learn more about Gilson cannabis purification products, systems, and services.

Solutions for the Cannabis Industry

With over 40 years of experience in preparative and industrial chromatography, Gilson Purification services teams have worked hand-in-hand with cannabis researchers and businesses, bringing them:

Extensive command of the entire processing workflow and the main purification techniques applied with cannabis (prep HPLC, flash, and CPC)

Access to state-of-the-art databases and lab facilities built to address research, pilot, and process scale challenges

End-to-end services from feasibility study to production, including industrial intensification, operator training, and product value optimisation

Solve Scientific offering easily accessible local, reactive service and support that can be provided directly at your site or real-time via dedicated software and tools solutions.

Cannabidiol (CBD) is a non-psychotropic cannabinoid from the Cannabis sativa L. (Cannabaceae) plant. Researchers have shown that CBD’s medicinal properties may be of use for treating a variety of conditions including pain, inflammation, epilepsy, and cancer. Changes in the legal status of cannabis for medical use, along with the increasing number of therapeutic applications for CBD, has resulted in rapidly growing demand for highly pure CBD. As such, it is crucial to develop standardised CBD products free of unwanted components to ensure patient safety. CBD manufacturers will require efficient, cost-effective methods that can produce high yields of impurity-free products.

This article describes a rapid and reproducible method for large-scale purification of pure CBD using CPC.

CPC purification of Cannabidiol

Single-step purification of cannabinoids by CPC

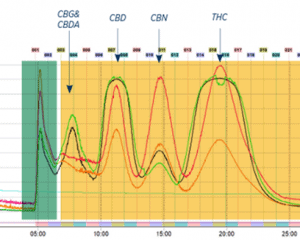

CPC is recognised as the preferred technology for the purification of high quality Δ-9-tetrahydrocannabinol (THC) and cannabidiol (CBD) for the pharmaceutical and food supplement markets. The objective of this app note was to test the high selectivity of CPC and assess its capability to purify a set of key compounds (THC, CBD, CBN and CBG) and enrich several minor cannabinoids (CBDV, CBCV and CBC).

Δ-9-tetrahydrocannabinol (THC) content in cannabis products, such as food supplements, vapes, or medicinal matrices, is strictly regulated in most countries worldwide. This has fuelled demand for broad spectrum THC-free oil, and spurred interest in THC remediation technologies applicable at industrial scale level. CPC is a preferred technology with natural product purification due to its ability to extract, remove or purify a target compound without denaturing or losing other compounds present with it in the sample.

This application note demonstrates the added value of CPC for THC remediation of multiple tons of full-spectrum oil.

Multi-ton processing of cannabis oil for remediation by CPC

Solutions for the Cannabis Industry

Introduction to CPC

Natural product purification systems

VERITY CPC Process System