SOLUTIONS FOR THE NATURAL PRODUCTS INDUSTRY

NATURAL PRODUCT PURIFICATION

Simplify workflows with Gilson’s VERITY CPC Systems

The right choice for natural product purification

Next-generation label-free analysis

BLI is a powerful technology that is flexible, highly-sensitive and accessible. From experiment to analysis, characterise the widest range of molecules on a single easy-to-use platform ― in a single run.

True low volume, high throughput subvisible particle analysis

Aura systems help you develop stable, pure, and efficacious protein, cell, and gene therapies faster. By combining the sensitivity of BMI with fluorescent detection, Aura systems enable high-throughput particle count, size and identification.

Next-generation label-free analysis

BLI is a powerful technology that is flexible, highly-sensitive and accessible. From experiment to analysis, characterise the widest range of molecules on a single easy-to-use platform ― in a single run.

True low volume, high throughput subvisible particle analysis

Aura systems help you develop stable, pure, and efficacious protein, cell, and gene therapies faster. By combining the sensitivity of BMI with fluorescent detection, Aura systems enable high-throughput particle count, size and identification.

The right choice for natural product purification

Home - Natural Product Purification

CPC is ideal for extract fractionation and compound purification when isolating active compounds from complex, crude, natural product extracts. CPC is a cost-effective alternative to standard purification techniques, such as flash and prep HPLC, and yields a high quantity of pure compounds. Gilson’s VERITY CPC Systems are very configurable and can be tailored to meet your particular needs. They are adaptable for purifying a wide range of compounds from complex natural product extracts.

Ideal for isolation of biologically active natural products

Since CPC uses a silica-free liquid-liquid chromatographic technique, it does not denature fragile molecules. There is no irreversible sample adsorption to the matrix; therefore, no sample loss, resulting in higher yields. Gilson’s VERITY CPC Systems can tackle challenging separations of complex samples in a single step without prior purification, making it the ideal choice for natural extract fractionation and compound purification.

An efficient, green and streamlined workflow

The reusable, silica-free columns offer high injection capacities of milligrams to kilograms. There are no columns to replace or silica to recycle and no risk of blocked or contaminated columns. The VERITY CPC System uses five times less solvent and eliminates the need for pre-treatment before injection. Adding mass triggered purification improves collection selectivity when working with highly concentrated or complex samples. Automatically confirming the molecular weight of the contents of every collected fraction during purification simplifies workflows, saves time and maximises productivity.

High yield, reproducible, fast and scalable

Achieve 95% recovery and > 99% purity with Gilson’s VERITY CPC Systems that provide a simple, rapid process with easy scale-up, full integration, high yields and minimal product loss. Gilson’s VERITY CPC Process systems are GMP compatible to future proof your process with the flexibility to grow from research to industrial scale.

Introduction to CPC

Natural product purification systems

Cost-effective cannabinoid purification

Introduction to CPC

Natural Product purification systems

Cost-effective cannabinoid purification

Chromatographic purification of natural compounds presents many challenges to scientists because of the complex nature of the starting matrices that are used in the process. Rather uniquely, CPC uses both liquid stationary and mobile phases and as such can handle heavily contaminated, complex starting materials such as direct extracts from many biological sources.

Separation is based on liquid-liquid partitioning:

From lab to industrial scale, Gilson offers

solutions for isolating compounds

from natural products

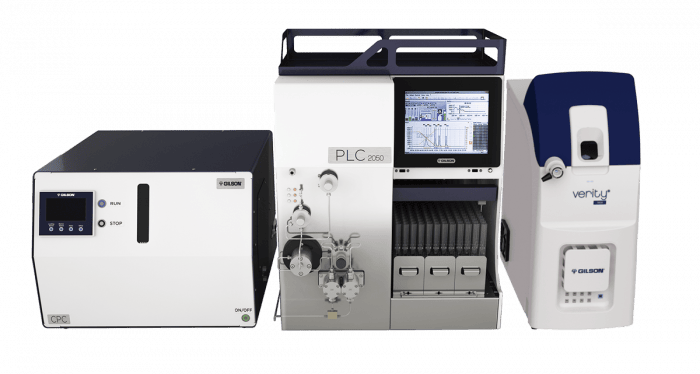

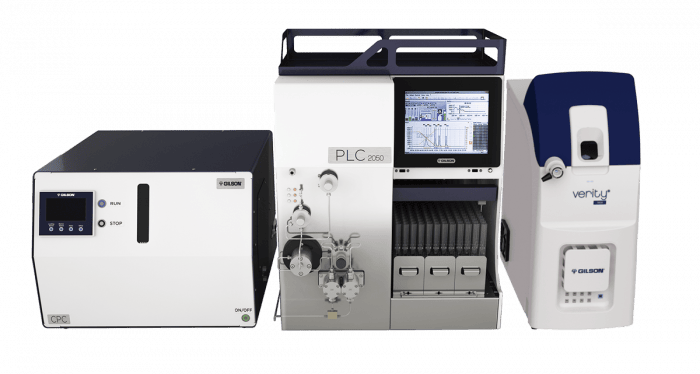

The VERITY CPC Lab MS System combines mass-directed purification of target compounds with all the benefits of CPC, allowing you to quickly isolate added value molecules from natural products with high yields and purity.

You’ll save valuable time and maximise productivity as targeted fraction collection reduces post purification work and purity analysis for extract validation and commercialisation.

Verity CPC Lab MS System

Mass spec – a modular addition to VERITY CPC Systems

The VERITY CPC Lab MS System combines mass-directed purification of target compounds with all the benefits of CPC, allowing you to quickly isolate added value molecules from natural products with high yields and purity.

You’ll save valuable time and maximise productivity as targeted fraction collection reduces post purification work and purity analysis for extract validation and commercialisation.

Verity CPC Lab MS System

Gilson don’t just develop market leading technology. Their dedicated and experienced teams are available to make sure that you get the best from their systems with a range of purification services including engineering design, application development, feasibility and scale-up studies, qualification support, and installation services as part of operational ramp-up.

Solve Scientific as Gilson’s exclusive instruments representative, have local staff each with over 25 years’ experience working with Gilson.

Together, with the backing of a global network of CPC Application Specialists, CPC Service & Validation Engineers, and factory support from Gilson’s CPC Centres of Excellence, Solve Scientific can uniquely provide Australian and NZ customers easily accessible local expertise with applications tailored to serve business strategies, and service and support to keep instruments running at peak performance.

There are many applications for CPC systems within the natural products space, including purifying cannabinoids from cannabis oil, removing THC from cannabis oil, purifying omega-3 fatty acids from microalgae, and purifying steviosides from stevia.

CPC is recognised as the preferred technology for the purification of high quality Δ-9-tetrahydrocannabinol (THC) and cannabidiol (CBD) for the pharmaceutical and food supplement markets. Changes in the legal status of cannabis for medical use, along with the increasing number of therapeutic applications for CBD, has resulted in rapidly growing demand for highly pure CBD. As such, it is crucial to develop standardised CBD products free of unwanted components to ensure patient safety. CPC can provide CBD manufacturers efficient, cost-effective, high selectivity methods that can produce high yields of impurity-free products.

Read more about the use and benefits of CPC in the purification of cannabinoids from crude cannabis oil.

CPC is recognised as the preferred technology for the purification of high quality Δ-9-tetrahydrocannabinol (THC) and cannabidiol (CBD) for the pharmaceutical and food supplement markets. Changes in the legal status of cannabis for medical use, along with the increasing number of therapeutic applications for CBD, has resulted in rapidly growing demand for highly pure CBD. As such, it is crucial to develop standardised CBD products free of unwanted components to ensure patient safety. CPC can provide CBD manufacturers efficient, cost-effective, high selectivity methods that can produce high yields of impurity-free products.

Read more about the use and benefits of CPC in the purification of cannabinoids from crude cannabis oil.

Comparative purification of Cyn from green algae

This publication compares CPC and HPLC techniques for the purification of caulerpenyne (Cyn), an abundant, biologically active metabolite of Caulerpa taxifolia. HPLC analysis of the C. taxifolia crude extract showed many impurities and a low abundance of Cyn for isolation. Purification from this extract through Gilson’s VERITY CPC System resulted in a significant increase in the isolated Cyn mass and yield, reduced solvent consumption and run time as compared to HPLC.

This study demonstrates that CPC constitutes a very simple, high yielding and efficient process to access Cyn.

Purification of Caulerpenyne from Green Algae

As the drug resistance of malaria parasites increases, the development of innovative and effective antimalaria drugs is of high importance. Natural products provide a vast field of new lead structures that are effective in fighting the disease. A nor-cycloartane alkaloid from Buxus sempervirens has shown promising and selective in vitro antimalarial activity. The target compound occurs in a complex matrix consisting of numerous congeneric alkaloids. Hence, an efficient separation scheme is required.

In this app note, Gilson describes an efficient 2-step CPC purification process of the target alkaloid which yields high purity and recovery.

Purifying an antimalarial natural compound with CPC

As the drug resistance of malaria parasites increases, the development of innovative and effective antimalaria drugs is of high importance. Natural products provide a vast field of new lead structures that are effective in fighting the disease. A nor-cycloartane alkaloid from Buxus sempervirens has shown promising and selective in vitro antimalarial activity. The target compound occurs in a complex matrix consisting of numerous congeneric alkaloids. Hence, an efficient separation scheme is required.

In this app note, Gilson describes an efficient 2-step CPC purification process of the target alkaloid which yields high purity and recovery.

CPC Purification of an Antimalarial Alkaloid

Comparative vanillin purification

Vanillin is the major component of natural vanilla, which is one of the most widely used flavouring materials worldwide.

In this app note, an ethanolic crude extract of vanilla is used to show the capacity of Gilson’s PLC 2050 Purification System to work with different types of chromatographic columns, including CPC and preparative HPLC. Between the two techniques, CPC provides a more efficient option for complex extract treatment, with drastically reduced solvent consumption for lower cost and environmental impact.

Vanillin is the major component of natural vanilla, which is one of the most widely used flavouring materials worldwide.

In this app note, an ethanolic crude extract of vanilla is used to show the capacity of Gilson’s PLC 2050 Purification System to work with different types of chromatographic columns, including CPC and preparative HPLC. Between the two techniques, CPC provides a more efficient option for complex extract treatment, with drastically reduced solvent consumption for lower cost and environmental impact.

A Comparative Study in The Purification of Vanillin

Fermentation allows for the conversion of organic materials into relatively simple substances by using microorganisms such as bacteria, Streptomyces, filamentous fungi, or yeast.

In this app note, Gilson demonstrates the added value of CPC at achieving an efficient separation from a fermentation broth in one step. While the original prep chromatography process delivers the target compound with 65% purity, CPC achieves > 94% purity from the crude sample. Additionally, CPC provides a 55% reduction in solvent consumption at lab level and demonstrates capability to achieve similar results scaled up, processing multiple tons per year in a GMP environment.

Applying CPC to bioprocessing downstream purification

Fermentation allows for the conversion of organic materials into relatively simple substances by using microorganisms such as bacteria, Streptomyces, filamentous fungi, or yeast.

In this app note, Gilson demonstrates the added value of CPC at achieving an efficient separation from a fermentation broth in one step. While the original prep chromatography process delivers the target compound with 65% purity, CPC achieves > 94% purity from the crude sample. Additionally, CPC provides a 55% reduction in solvent consumption at lab level and demonstrates capability to achieve similar results scaled up, processing multiple tons per year in a GMP environment.

Bioprocess Downstream Purification with CPC

CPC purification of [6]-gingerol

Ginger is widely known for its use in flavouring foods and beverages, but it is also commonly used for medicinal, perfumery, and aesthetic purposes.

This app note shows how CPC can produce a high-quality standard of [6]-gingerol without the use of silica-based chromatography methods.

Ginger is widely known for its use in flavouring foods and beverages, but it is also commonly used for medicinal, perfumery, and aesthetic purposes.

This app note shows how CPC can produce a high-quality standard of [6]-gingerol without the use of silica-based chromatography methods.

CPC for Flavouring Industries

Piperine is a pungent alkaloid that confers the biting taste to black pepper, and is a molecule of therapeutic interest, being used in many traditional medicines. Peppercorns, the dried fruits from Piper nigrum, contain approximately 2 % – 9 % piperine by mass.

In this app note, Gilson develop a purification method for piperine using CPC with mass-directed fraction collection. The method is rapid and reproducible, recovers close to 100% of the piperine from a complex crude extract, requires less solvent than other LC methods and can be easily scaled up from milligram to multi-kilogram scale. Mass-directed fraction collection minimises the number of fractions collected, thereby reducing the time required for sample analysis. This approach has the added advantage of coupling high recovery with direct identification of the target compounds.

Purification of Piperine with

mass-directed CPC

Piperine is a pungent alkaloid that confers the biting taste to black pepper, and is a molecule of therapeutic interest, being used in many traditional medicines. Peppercorns, the dried fruits from Piper nigrum, contain approximately 2%–9% piperine by mass.

In this app note, Gilson develop a purification method for piperine using CPC with mass-directed fraction collection. The method is rapid and reproducible, recovers close to 100% of the piperine from a complex crude extract, requires less solvent than other LC methods and can be easily scaled up from milligram to multi-kilogram scale. Mass-directed fraction collection minimises the number of fractions collected, thereby reducing the time required for sample analysis. This approach has the added advantage of coupling high recovery with direct identification of the target compounds.

CPC for Flavouring Industries

Introduction to CPC

Natural product purification systems

Cost-effective cannabinoid purification